3D Automatic Copper Condenser Tube Bending Machine for Sale

$22,320.00

Price in reward points: 22320- Brand: 未设置品牌

- Product Code: FW230910857152

- Availability: 500

Product Description

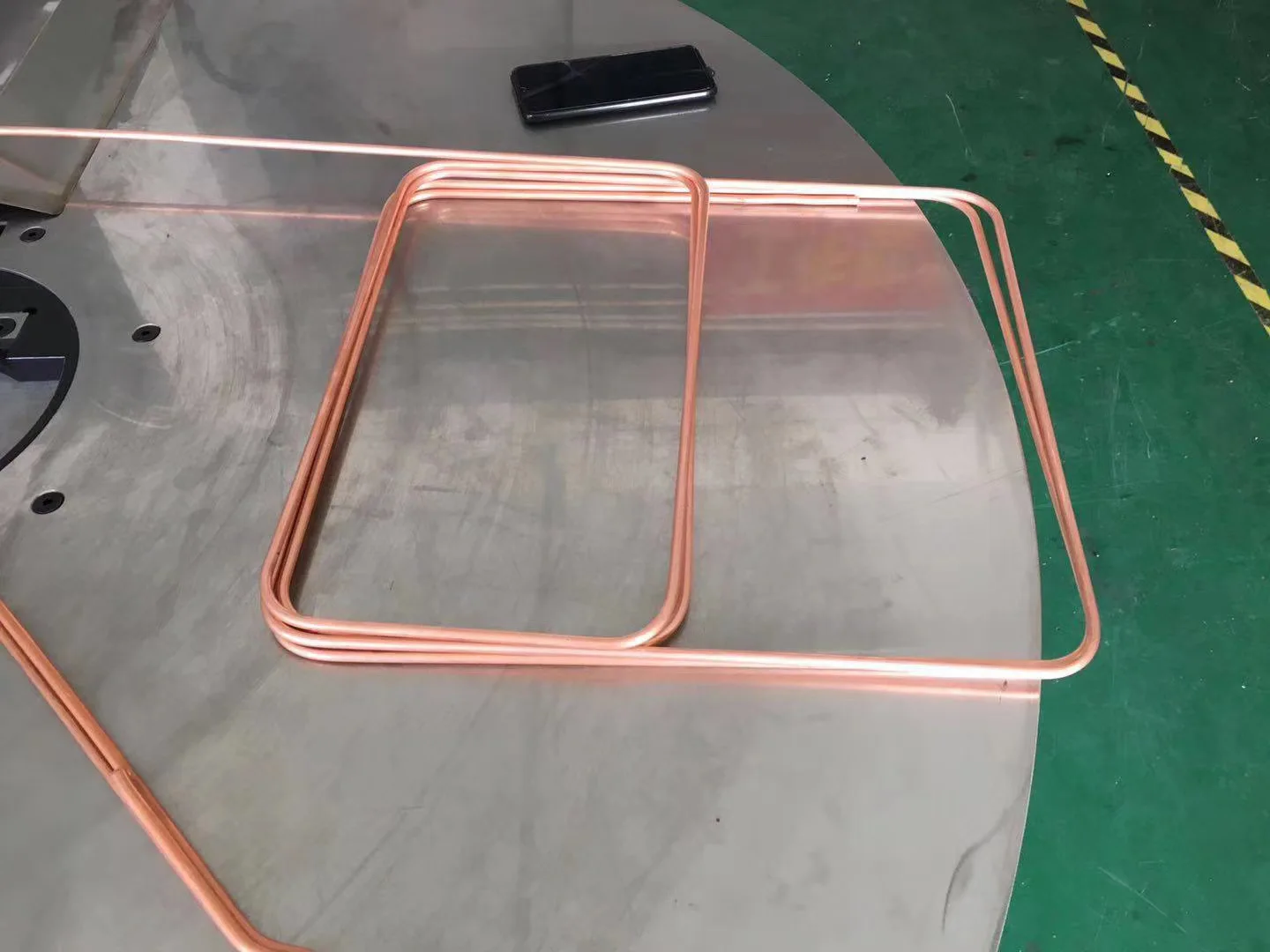

The WA series serpentine bender is widely used for steel bundy tube bending process. Widely used for condenser, heat exchanger making. Compare to traditional manual bending work, the semi-automatic bending machine can process up to 10-12 grouped tubes in one time bending according to various tube diameters, the work efficiency is much more upgraded, and the finished tube presents good appearance as per requirements.

Features:

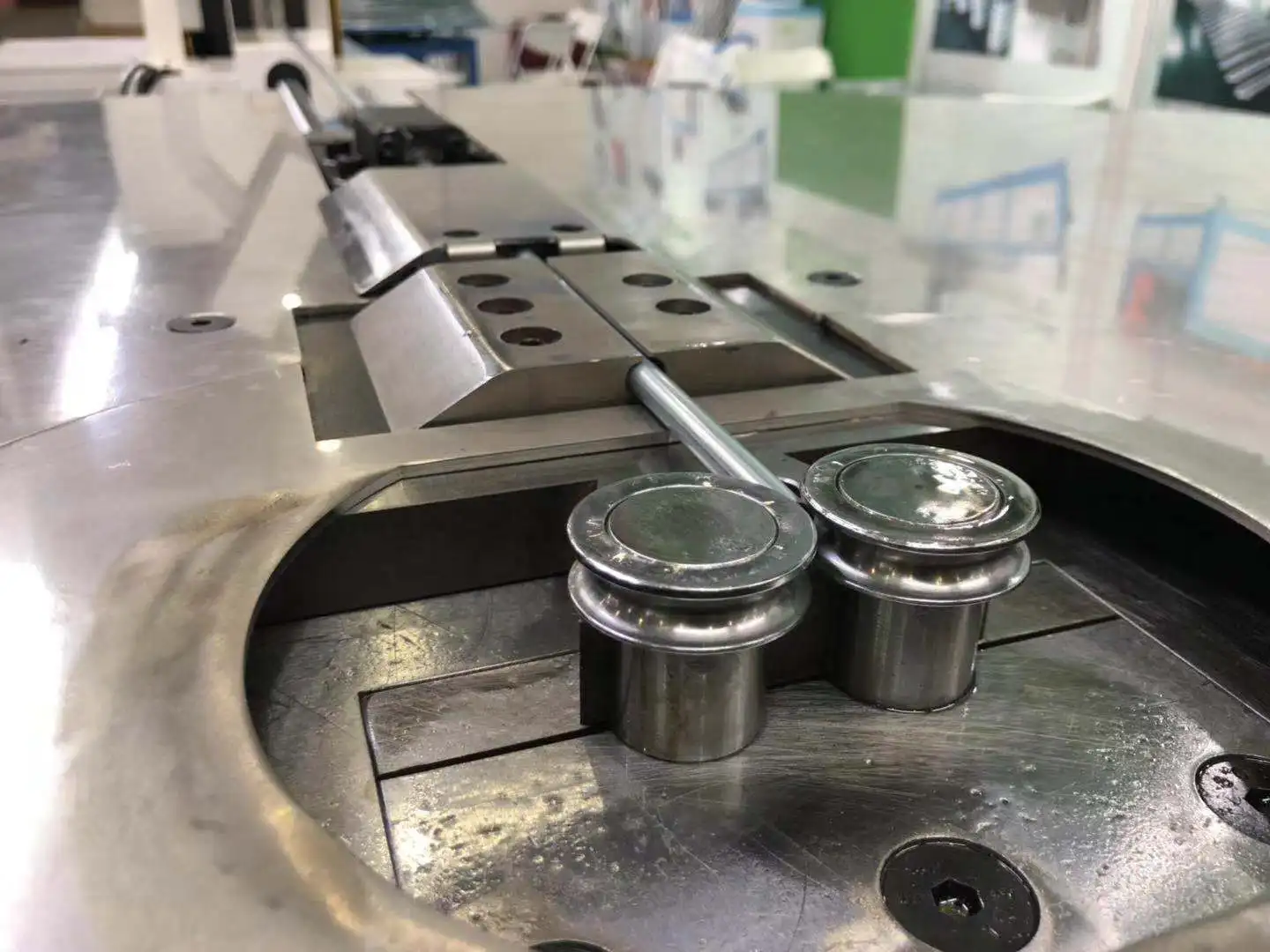

1. Patented special designed servo control bending system for different bending direction and bending angle in exact size. 2. Patented special designed bending tools ensure exact bending radius, less deformation and good appearance

3. Patented special designed bending structure ensures the stable performance for up to 10-12 grouped tubes in one time. 4.Servo drive system, PLC control system, and touch screen control to get high accuracy product size with easy operation and maintenance.

5. Matched with automatic tube chipess cut to length machine, the semi-automatic serpentine bender takes large output capacity with less fault and breakdown.

5. Matched with automatic tube chipess cut to length machine, the semi-automatic serpentine bender takes large output capacity with less fault and breakdown.

Specification

NO. | Parameter | Data |

1 | Tube Material | Steel Tube / Bundy tube |

2 | Tube Diameter | Φ3-12mm |

3 | Tube Wall Thickness | 0.3-1.0mm |

4 | Bending Capacity | 1-12 pcs / cycle |

5 | Bending Angle | 1~180 degree |

6 | Bending Radius | R15~R35 |

7 | Bending Times | Up to 110 times/cycle |

8 | Feeding length | 0-700mm/time, max. 3 times |

9 | Worktable Size | Φ1800mm |

10 | Control System | PLC control / Touch Screen |

11 | Motor Power | 5.0KW |

12 | Electric System | 380V, 50Hz, 3Phae (Customized) |

13 | Dimension | 2200 x 1000 x 1580 mm (Excluded Table) |

14 | Weight | About 1300 KG |

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

| Applicable Industries | Manufacturing Plant |

| Application | tube bending machine |

| Automation | Automatic |

| Bending Precision (Deg) | / |

| Condition | New |

| Control | CNC |

| Core Components | Engine |

| Key Selling Points | Automatic |

| Machine Type | bender |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Material / Metal Processed | Brass / Copper;Aluminum |

| Max. Bending Angle (Deg) | 180 |

| Place of Origin | China |

| Power (kW) | 5 |

| Raw Material | steel tube |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Warranty | 1 Year |

| Warranty of core components | 1 Year |

| Weight (KG) | 1300 |